Zara International provides the best Automatic Air Bubble Bag Making Machines manufacturer, supplier, and dealer in India, Himachal Pradesh, Punjab, Chandigarh, Haryana, Uttarakhand, New Delhi, Uttar Pradesh, Lucknow, Varanasi, Prayagraj, Bihar, Patna, Jharkhand, Dhanbad, Bengal, Odisha, Visakhapatnam, Chhattisgarh, Nagpur, telangana, vijayawada, Andhra Pradesh, Chennai, Bengaluru, Tamilnadu, Madurai, Kerala, Mysuru, Karnataka, Goa, Maharashtra, Mumbai, Gujarat, Ahmedabad, Surat, Rajkot, Madhya Pradesh, Indore, Ujjain, Kanpur, Kota, Rajasthan, Jaipur, and Ajmer. Owing to our state-of-the-art manufacturing unit comprising latest machinery, we are able to fabricate various high-performing machines. These machines are also subjected to stringent quality tests prior to dispatch. Moreover, our expert professionals endeavor to offer an innovative range of designs as per the market trends to lend optimal satisfaction to our clients.

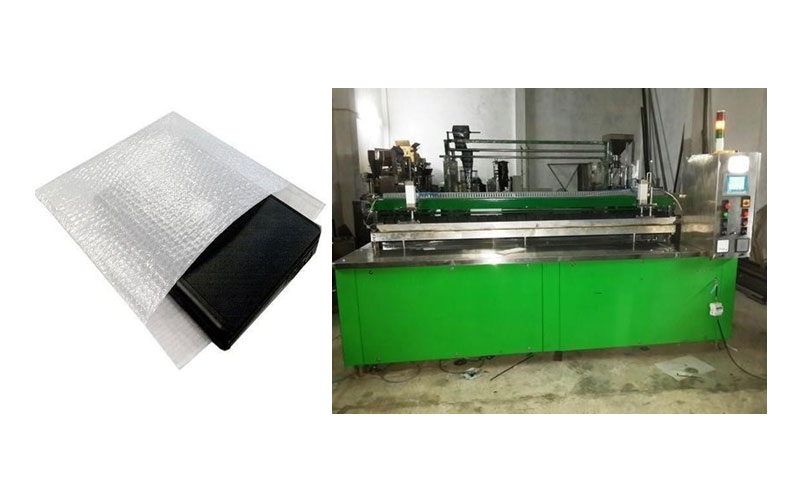

Product: EPE, AIR BUBBLE Roll

Model number: ZI2001

Max & Min Size of Bag: 1000 mm & 50 mm width

3 Side Seal L-SHAPE degree folder assembly for prepare bags epe / air bubble for 700 mm model

Digitally length control Zero time for changing the size of the bag.

Epe/air bubble open ONE side and two side seal from machine and one side fold from folder.

Heavy-duty and accurate automatic pulling system through imported rubber rollers.

Heavy Duty Cladding Rollers for moving rolls easily.

Complete Programming Logically Controlled System (P.L.C) (Make: OMRON, SIEMENS)

Stainless steel front table for collection of production bubble bags.

Imported Teflon Coating Heaters for safety bubble / epe roll sticky nature

Digitally Touch Display for parameter setting of machine (Make: OMRON, SIEMENS)

Gear Box with connected load 1.0 (Make: ROTOMOTIVE, BONVARIO)

Servo-Controlled Motor 0.75 HP for 700 mm-size Roll (Make: OMRON SIEMENS)

Speed capacity up to 30 Bags per minute (Bubble up to 25 Bags) DEPEND ON THE ROLL THICKNESS AND SIZE

Variable sealing time to suit different thickness and different materials.

Connected Load is available in three phases and a single phase as per customer demand.

Construction: All Around Mild Steel Covered with a Painted Border

Adjustable sealing temperature time through PLC.

Pneumatic technology is used for efficient pouch sealing or cutting.

Heavy Duty Aluminum Grade Pneumatic Cylinders for sealing pouches (Make: SMC)

Weight of the machine should be 340 Kgs with folder

Air compressor required 3–4 CFM with 6 KG BAR pressure. (CUSTOMER SCOPE)

Why Choose Us For The Best Automatic Air Bubble Bag Making Machines Manufacturer?

Superior Automation: Modern automation technology in our equipment guarantees smooth operation and reduces the need for manual intervention. This lowers operating expenses and increases productivity.

Outstanding Quality: Our machines are built with sturdy materials and creative designs that provide long-lasting performance, allowing for the reliable manufacturing of high-quality air bubble bags.

Personalization Choices: Our machines can be customized to meet your unique needs, whether you require standard-sized bubble bags or special specs.

Efficiency of Energy: Our machines are built to use as little energy as possible while still providing excellent performance, allowing you to lessen your carbon footprint.

Conclusion: We take great satisfaction in having years of experience and a solid reputation in the field. Our cutting-edge production plant and staff of knowledgeable experts enable us to provide equipment that seamlessly blends efficiency and creativity. We provide the best Automatic Air Bubble Bag Making Machines manufacturer supplier and dealers in India, Himachal Pradesh, Punjab, Chandigarh, Haryana, Uttarakhand, New Delhi, Uttar Pradesh, Lucknow, Varanasi, Prayagraj, Bihar, Patna, Jharkhand, Dhanbad, Bengal, Odisha, Visakhapatnam, Chhattisgarh, Nagpur, telangana, vijayawada, Andhra Pradesh, Chennai, Bengaluru, Tamilnadu, Madurai, Kerala, Mysuru, Karnataka, Goa, Maharashtra, Mumbai, Gujarat, Ahmedabad, Surat, Rajkot, Madhya Pradesh, Indore, Ujjain, Kanpur, Kota, Rajasthan, Jaipur, and Ajmer.